About Us

- Home

- About Us

About Us

MICRON ENTERPRISES, an IATF 16949:2016 Company, is a pioneer organization specializing in manufacture and export of Universal Joint Crosses in India. Envisaging the vision to excel, we launched our operations in 1997.

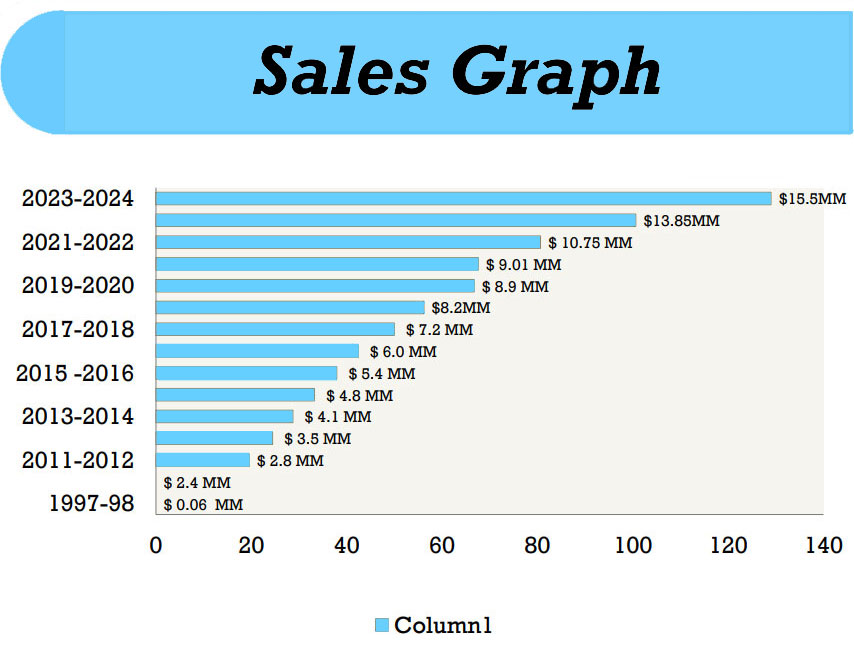

The company started in 1997 as a small scale manufacturing facility with Conventional machines and a covered area of 2000 sq.ft to produce 3000 Pcs U.J. Cross per month making a turnover of almost 45lac First Year. Gradually it has modified into a high class manufacturing facility of 100000 sq. Ft. with a number of CNC Turning Centers, CNC SPM's along with a modern Heat Treatment and Metallurgical lab has reached a production of almost 200,000 Pcs U.J. Cross per month in the Year 2023-2024 taking the Turnover of the Company to $ 15.50 Million.

Micron is a Multifaceted, debt free cash rich company engaged in Real Estate and Finance business. We have a huge investment in stock and Mutual Funds. Hence any type of new venture can be started very quickly.

Micron has a big List of satisfied domestic corporate customers as well as overseas customers. Domestic Corporate are buying U. J. Cross in their own brand in more than One Hundred Thousand No’s per year per customer.

Vendor Park

We have many bought out parts like cold forging, rubber seals, circlips, nylon thrust washers, plastic caps, grease nipples etc. It was difficult to buy these parts from outside and maintain quality control especially at our volumes due to which we created a small vendor park for our major vendor.